The EnviroSim team is pleased to announce the release of BioWin 5.3.

BioWin 5.3 contains a new Granular Sludge Sequencing Tank element to model this process, which is gaining acceptance worldwide as an effective wastewater treatment technology. BioWin 5.3 also contains an enhancement to the trickling filter element and refinements to model parameters.

A more comprehensive description of the upgrade may be found in a What's New in BioWin 5.3 in PDF format.

BioWin 5.3 highlights include:

- Granular Sludge Sequencing Tank

- Element Enhancement – Trickling Filter

- Default Parameter Changes

- Usability Feature

- Instructions for Annual License Customers

- Instructions for Perpetual License Customers

- Instructions for Academic License Customers

- Download BioWin 5.3

Granular Sludge Sequencing Tank

A Granular Sludge Sequencing Tank (GSST) element is available to represent this process in BioWin configurations. The modeling approach uses BioWin’s one-dimensional dynamic biofilm model to mimic the granular sludge. A one-dimensional layered solids flux model is applied for modeling settling of non-granular flocculent mixed liquor solids during unaerated/unmixed periods. These models are integrated with the general ASDM in a variable volume unit that allows various phases of operation to be specified. The GSST model has been developed to balance pragmatic design elements with mechanistic modeling rigor, to provide quick solution times, and typical process performance predictions.

Most GSST technology implementations employ a repeated batch-fed process. The microorganisms responsible for the majority of the carbon, nitrogen and phosphorous removal grow in dense granules rather than conventional activated sludge flocs. These granules settle rapidly, eliminating the need for separate settling tanks. The granules have a layered structure that may be more aerobic on the outside and anoxic or anaerobic towards the centre. This structure allows the granular sludge to simultaneously remove carbon, nitrogen and phosphorous from the wastewater in a single reactor/settler.

Element Enhancement – Trickling Filter

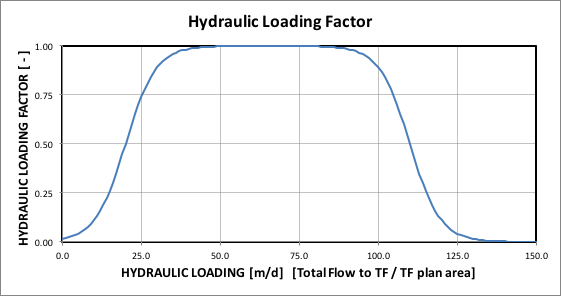

Hydraulic loading may impact the area available for gas transfer. If the wetting rate is too low then not all of the media will be “wet” so the gas transfer area will be reduced. On the other hand, if the hydraulic loading rate gets too high then it is possible that the air spaces between the media become filled with liquid, which also will reduce the available gas transfer area. The Hydraulic Loading Factor attempts to account for these less-than-optimal conditions. The Hydraulic Loading Factor is determined by a two-sided continuous switching function.

Over an optimal range of hydraulic loading the Hydraulic Loading Factor is equal to or close to unity (1). The value decreases towards zero for extreme low or high loading rates. The form of the continuous switching function is defined by the Low hydraulic loading rate switch value and the High hydraulic loading rate switch value. These are the low and high hydraulic loading rates where the Hydraulic Loading Factor has a value of 0.5 (i.e. the area for gas transfer is reduced to half of the effective area). Different media types have characteristic high and low loading rates.

In BioWin 5.3 we improved the continuous switching function of the hydraulic loading factor so that the trickling filter more accurately calculates the available area for gas transfer at extreme low or high loading rates. Our extensive testing has shown that the improved continuous switching function brings the predicted nitrification performance in line with measured data for numerous full-scale trickling filters under extreme low or high loading rates. The hydraulic loading factor plots for rock media and non-rock media/other media types are shown below:

Default Parameter Changes

Biofilm Attachment / Detachment Rates

Particulate attachment and detachment rates have a major role in establishing biofilm thickness, dynamics, and system activity, similar to SRT in activated sludge. The biofilm model is employed in the media bioreactors, trickling filters, submerged aerated filters and granular sludge sequencing tank in BioWin. EnviroSim performed numerous model calibrations of these types of systems to measured BOD, ammonia, NOX and biofilm growth profiles from full-scale and pilot-scale plants. Through this extensive testing, we have revised the default biofilm attachment and detachment rates to 8 g/(m2d) and 8,000 g/(m3d), respectively. [The former respective attachment and detachment rates were 80 g/(m2d) and 80,000 g/(m3d), respectively].

OHO Dissolved Oxygen Half Saturation Coefficient

The ordinary heterotroph organism (OHO) dissolved oxygen (DO) half-saturation coefficient (KDO) is used in several OHO rate expressions (e.g. growth, decay) to switch off aerobic OHO activity under low DO conditions, and turn on anoxic processes in the presence of NOX. In previous versions of BioWin, the default value for this parameter was 0.05 mg O2/L. This meant that anoxic processes only would be turned on in the model under very low DO conditions, and BioWin was conservative in nitrogen removal predictions by default. This value was selected based on observations of laboratory and pilot-scale systems that typically had shallow liquid depths (relative to full-scale systems), vigorous mixing and/or high air flow rates – all of which combined to yield small sludge flocs and very little evidence of denitrification even at relatively low DO levels.

However, in full-scale systems, lower levels of mixing intensity as well as other non-idealities often result in some degree of denitrification occurring at low DO levels. To reflect this with its default parameter set, in BioWin 5.3 the default OHO KDO has been increased from 0.05 mgO2/L to 0.15 mgO2/L. Obviously, the user can adjust this parameter to best fit observed process behavior, however, BioWin 5.3 will be somewhat less conservative in its predictions than previous versions for nitrogen removal if there are low DO zones incorporated in the process flowsheet.

Further details on all new features in BioWin 5.3 can be found in the Help manual.

Usability Feature

Multiply a Column by a Factor

Users may now multiply a column of values by a factor. This is done by right clicking on the “Value” column and selecting “Multiply column” from the pop-up window. In the example below, the initial state variable concentrations in a variable volume bioreactor are multiplied by a factor of 2 to increase the starting concentrations in the mixed liquor.

Download BioWin 5.3

You can download the full installation for BioWin 5.3 using the link below.

NOTE : BioWin Updater will not automatically upgrade BioWin 5.2 or earlier versions to BioWin 5.3. You MUST run the full installation from the link provided. Thereafter the BioWin Updater will always be checking that your files are up to date :

Other important items to note:

- The upgrade to 5.3 will not affect older BioWin versions (BioWin 5.2 and earlier) which are separate applications. This means that users can keep their older copies of BioWin.

- We are emailing the registered contact for specific BioWin serial number(s). If an organization has multiple copies or users of BioWin, we would be pleased if the registered contact can advise other users of this new version and these upgrade instructions.

Annual License Customers

Annual license customers can now upgrade to BioWin 5.3; releases and upgrades are included in the annual lease and distributed electronically. Instructions on how to electronically upgrade to BioWin 5.3 can be found here.

Perpetual License Customers

Perpetual License customers who purchased after December 1, 2016 will be emailed instructions on how to electronically upgrade to BioWin 5.3 free of charge. If you have not received your upgrade email, please contact us. Customers who purchased BioWin prior to December 1, 2016 may order an upgrade here for US$3,300.

Academic Licenses

Academic licenses can now be upgraded to BioWin 5.3; releases and upgrades are included in the annually renewed license and distributed electronically. Instructions on how to electronically upgrade to BioWin 5.3 can be found here.

Enjoy your new BioWin 5.3. We look forward to your feedback.